BLOG

-

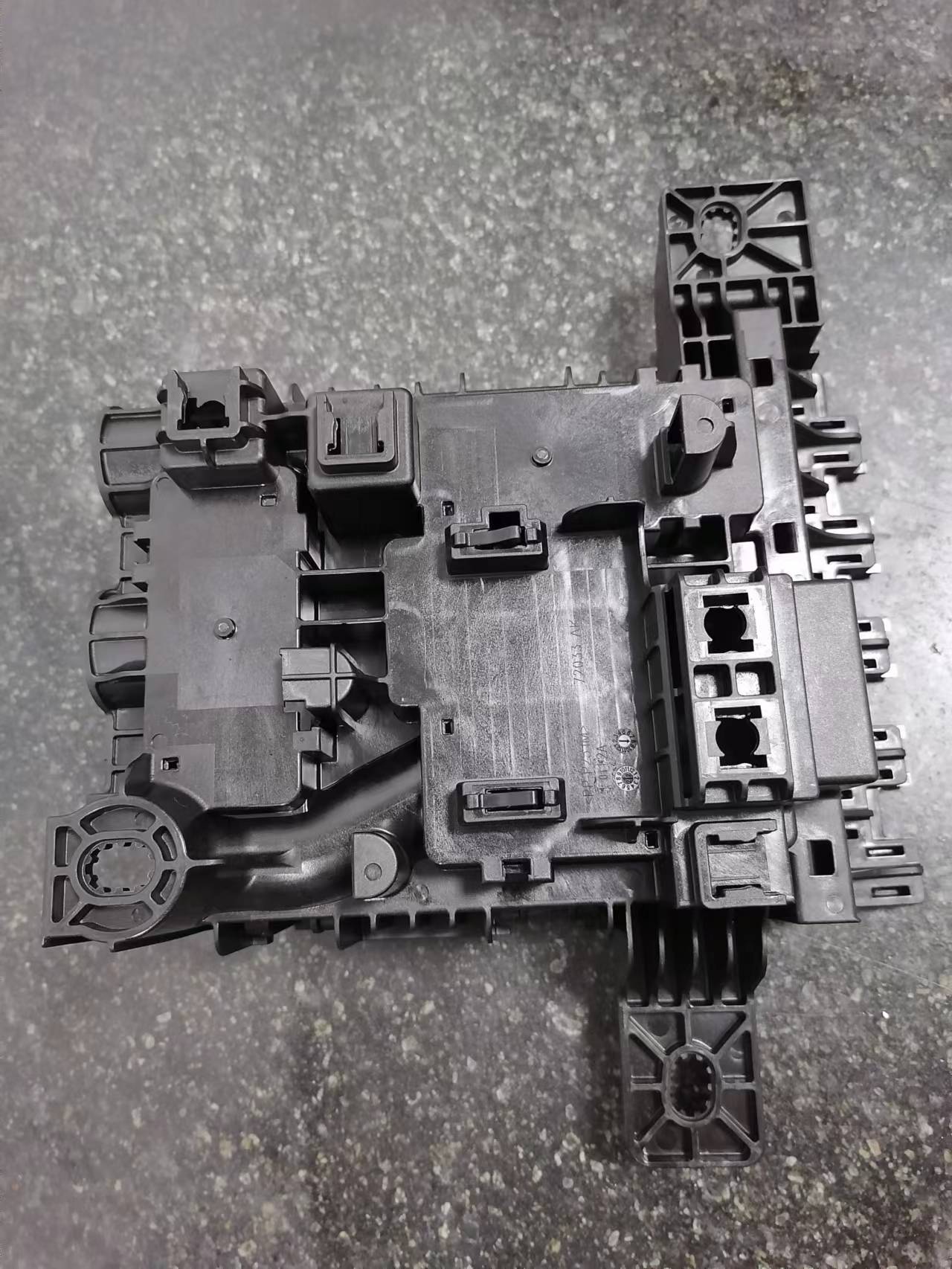

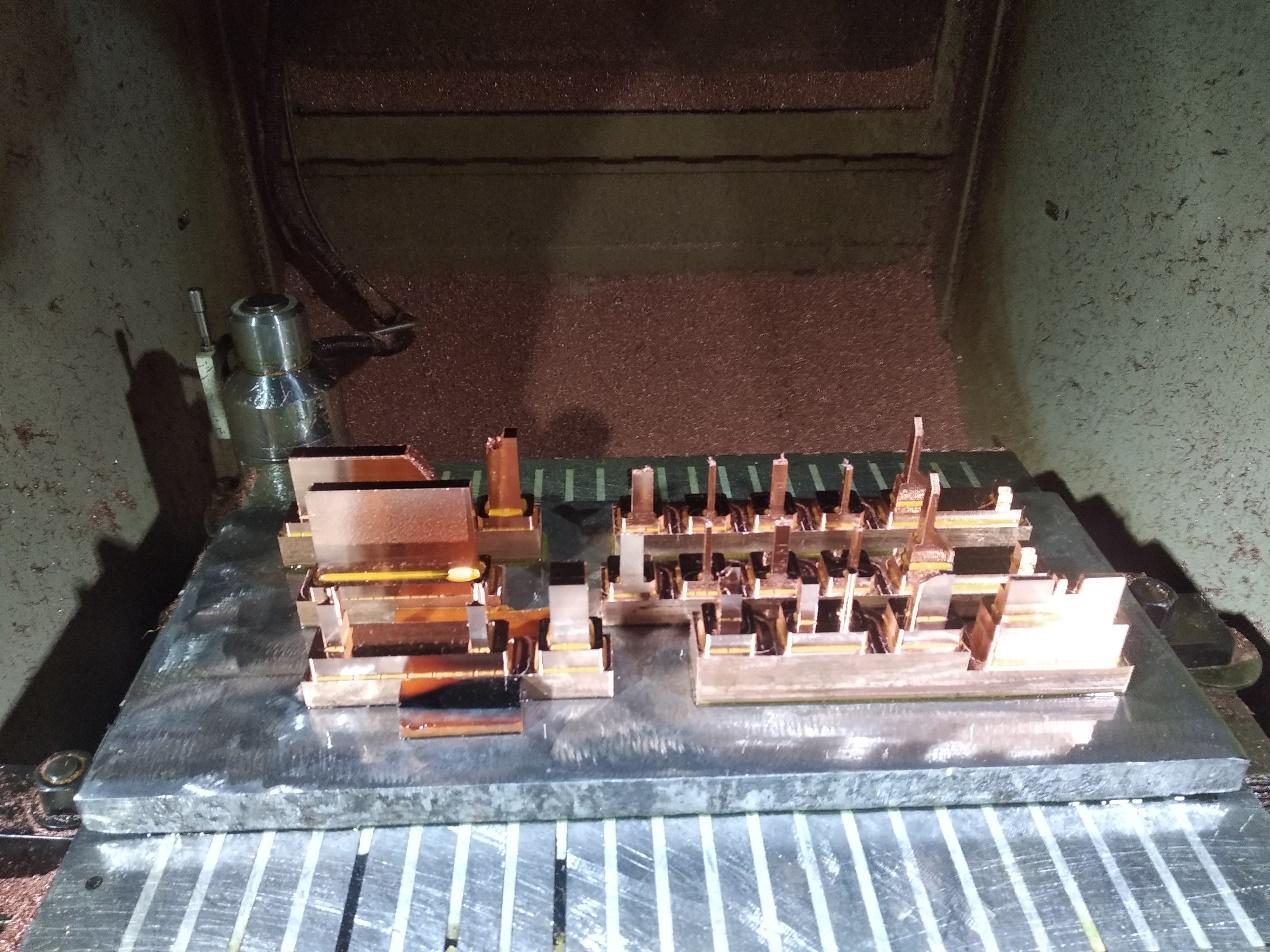

Plastic mold trial and mold inspection

Mold trial and mold inspection is the last work before the mold shipping. We need to understand the standards of mold testing and product acceptance, and timely perfect the mold so that the mold products are qualified to ship. There are three parts about mold acceptance, mold acceptance, mold tr...Read more -

How does Chapman maker improve the mold processing?

As a leading plastic product manufacturer, Chapman maker has been working diligently to improve the quality and technology of molds for their customers. With a focus on innovation and craftsmanship, Chapman maker has been able to provide customers with some of the highest quality molds available ...Read more -

Determination of the number of cavities and arrangement of cavities

According to the number of mold cavities, it can be divided into single-cavity injection mold and multi-cavity injection mold. The determination of the number of mold cavities is mainly based on the projected area of the product, geometric shape (with or without side core pulling), product precis...Read more -

Prototyping by rapid prototyping can achieve a balance of low cost and short cycle time

Exterior and interior parts are important components of a car, such as front and rear bumper skins, spoilers, and side skirts; interior parts are the parts that come into contact with the interior of the vehicle, such as Dashboard, sub-dashboard and door guard, etc. It is precisely because the in...Read more -

How does Chapman solve the unbalanced melt flow of multi -type mold?

During the injection process, there are many reasons for the imbalance of the melting flow. Among them, the flowing imbalance caused by temperature changes is particularly difficult to detect and avoid, which brings great inconvenience to injection molding production. So, is there any good way to...Read more -

Plastic mold&Injection production expert-Chapman maker

Chapman maker specializes in the manufacture of injection molds, design and manufacture of various general engineering plastics (ABS PP PC PS nylon PVC PET and other injection molding process plastic molding home smart appliances shell handicrafts industrial building mat...Read more -

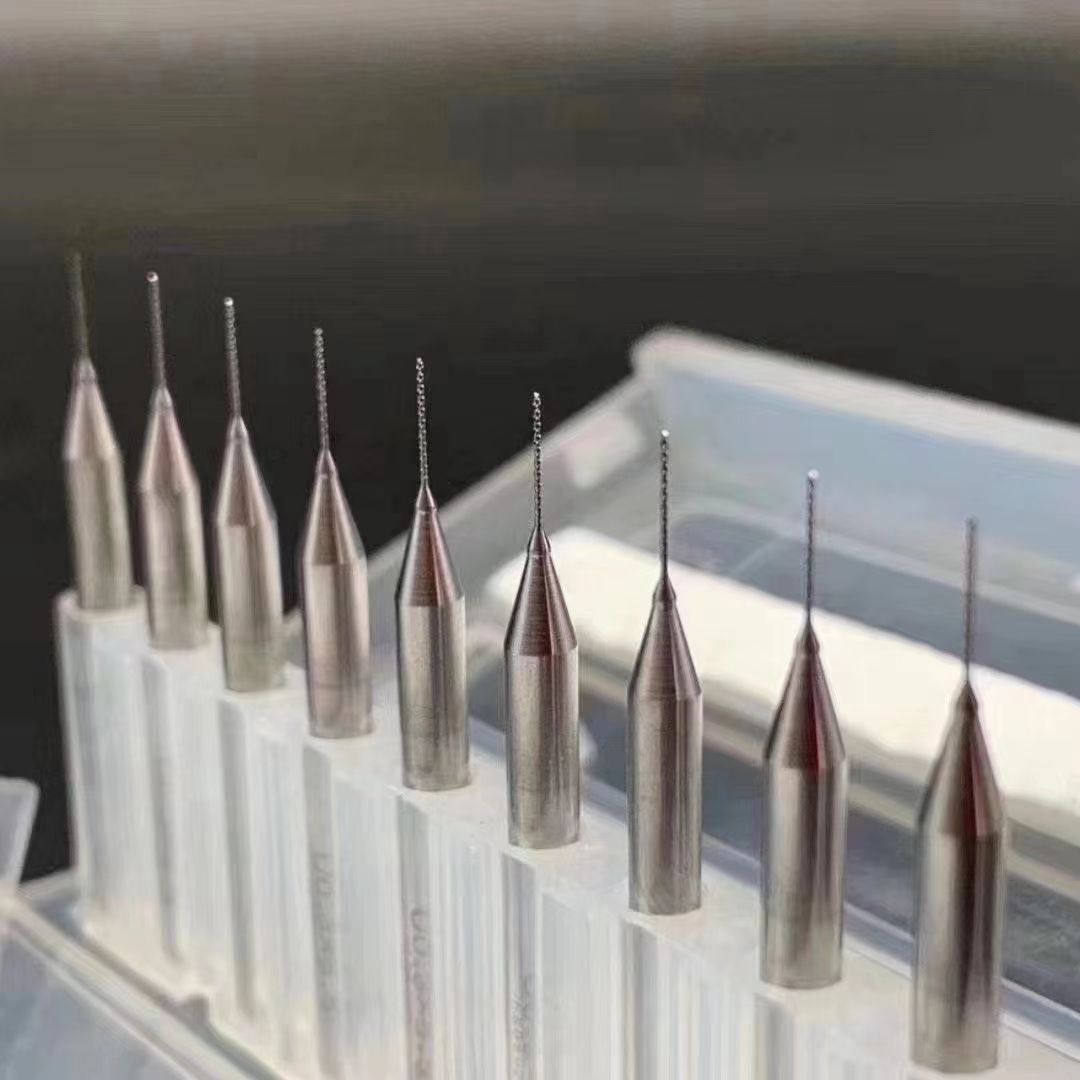

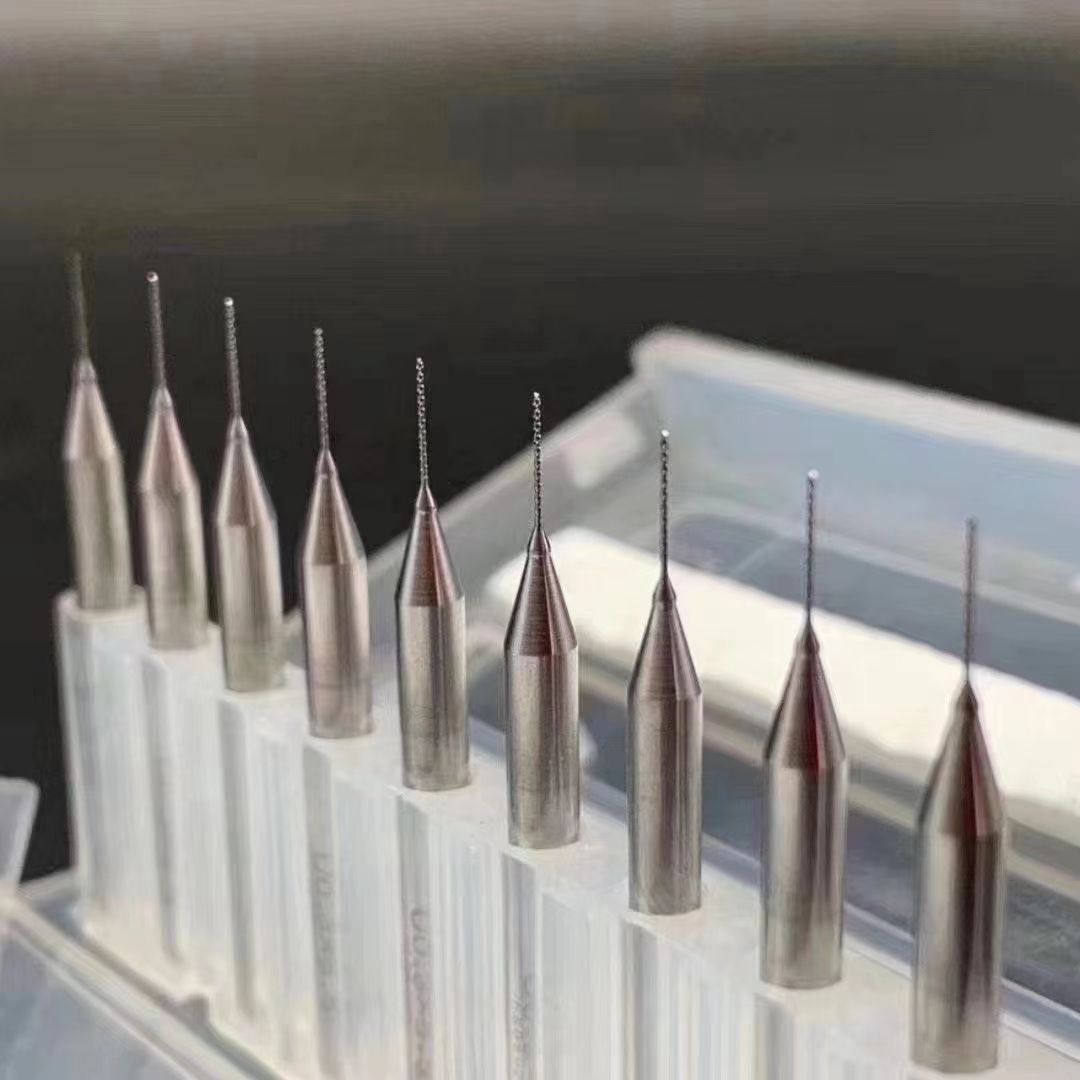

How does Chapman improve the precision of mold?

Mainly considering the 2 perspectives of mold design and mold processing.(In addition, the defects of the product itself will also affect the accuracy of the mold) 01 Mold design In the early stage of the product, the product flow analysis was made, and the more reasonable product inlet was foun...Read more -

Learn about the mold machining through Chapman

When some customers develop products or new product designs, they often only focus on product research and development or price in the initial stage, ignoring communication with mold manufacturers. After the product design plan is initially determined, it is necessary to...Read more -

Chapman tells you what problems to pay attention to when designing high-precision plastic molds

Chapman tells you what problems to pay attention to when designing high-precision plastic molds High-precision plastic molds have relatively high requirements for design, and the complexity of m...Read more -

This low-volume injection molding market that Chapman fills and serves

The injection molding process can be a very effective method of producing large quantities of plastic parts quickly and efficiently. Most injection molding machines produce plastic parts, often in the millions, and operate the machine 24 hours a day, 7 days a week. As the name suggests, l...Read more -

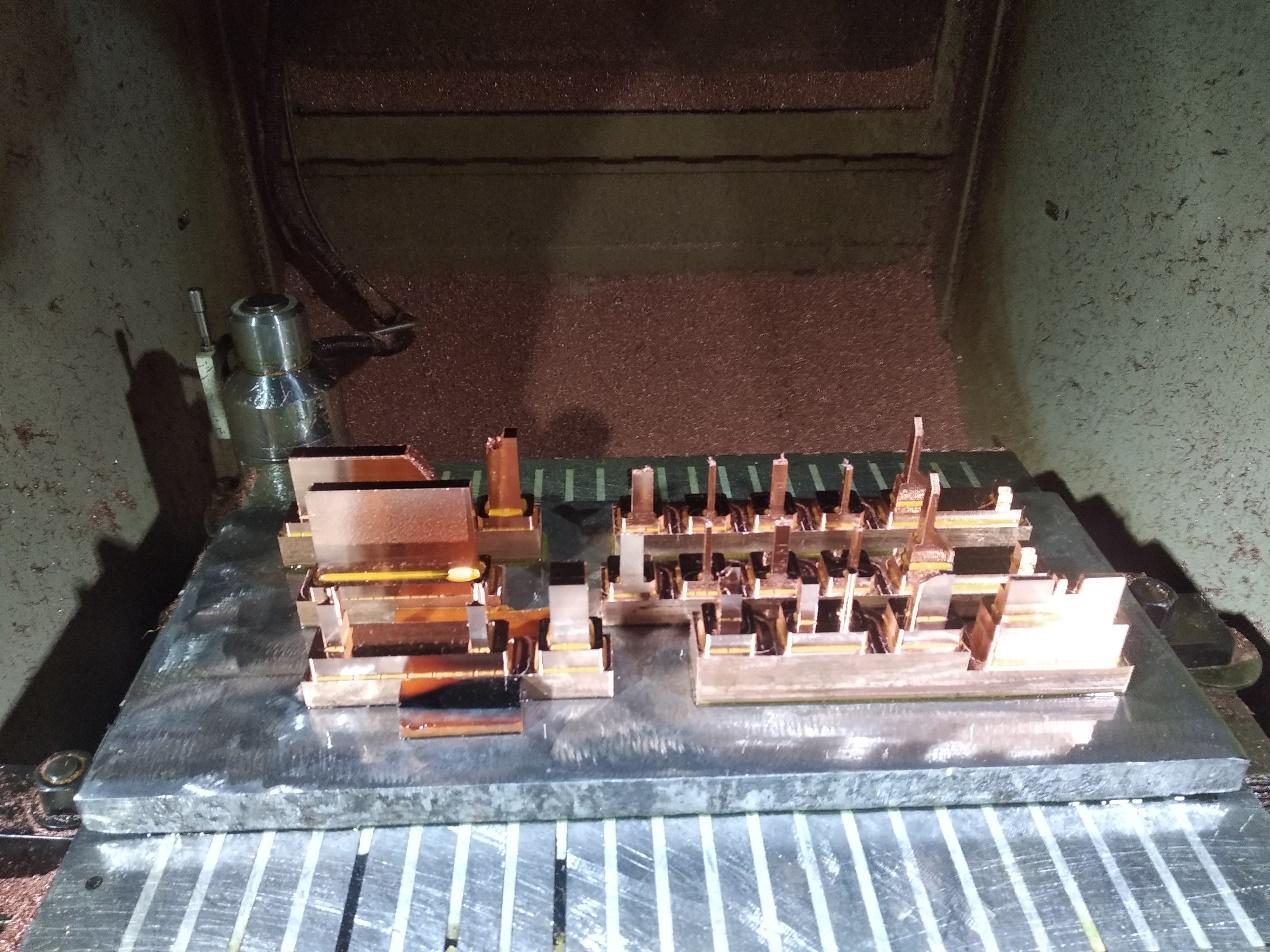

What are the processing methods of Chapman’s molds?

The machining methods of molds are generally divided into the following three types: (1) General machining General machining is our common turning. In the turning of molds, the main surface processing includes: internal and external rotating surface, spiral surface, end face, drilling, knurling,...Read more -

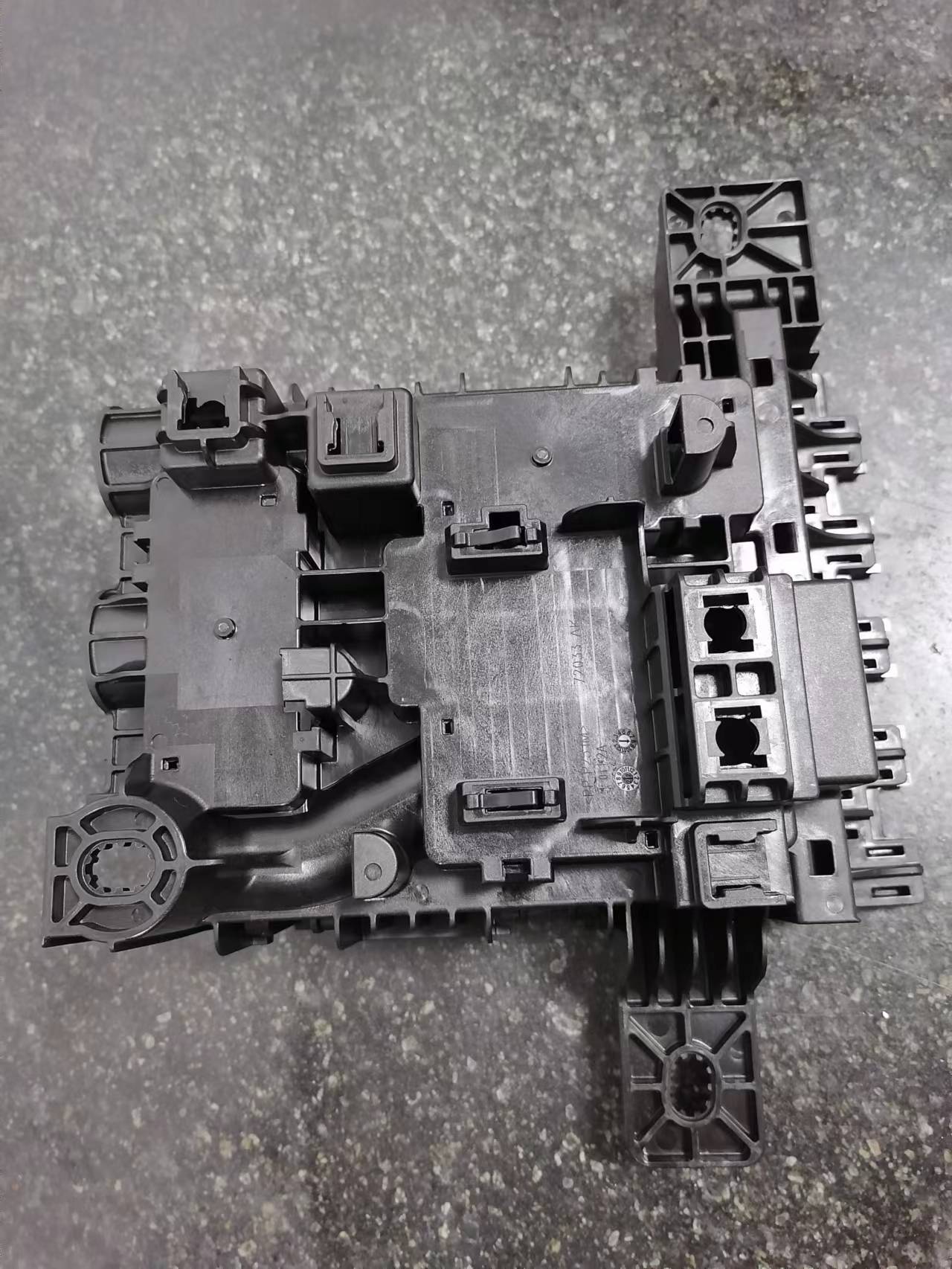

Chapman injection molding parts processing production and injection molding type introduction

Injection molding Injection molded parts refer to all kinds of injection molded products produced by injection molding machines, including various packages, parts, etc., which are mainly made of polyethylene or polypropylene and added with a variety of organic solvents. The selection of plastic ...Read more